ALLOYING ELEMENT FOR HOT DIP GALVANIZING INDUSTRY

In today's hot-dip galvanizing, the primary alloying elements in the zinc bath are lead, bismuth, nickel, and aluminum. These metals improve the coating's appearance, decrease zinc consumption, and improve the mechanical properties of the coating.

The use of lead in zinc baths has been restricted in many cases due to concerns about its impact on human health and the environment. Bismuth, which is an environmentally friendly alternative, is replacing lead. Adding approximately 0.1% Bi by weight to the bath results in liquid zinc flow of a similar amount from the product surface. Therefore, the required content in the bath is 10 times lower compared to the addition of Pb.

The optimal concentration of bismuth in the bath is typically in the range of 0.05% to 0.1% by weight.

Advantages of BISMUTH

- Increases the fluidity of the zinc by reducing the surface tension.

- Helps prevent bridged holes, clogged threads.

- Helps prevent runs in the zinc coating and zinc lumps.

- Safe for the environment and human health.

For the ideal kettle lifespan and to provide the maximum contribution to the zinc bath, the following formula should be considered.

10Bi + Pb < 1.3%

If Bi = 0.08% => Pb< 0.5%

Technical Properties

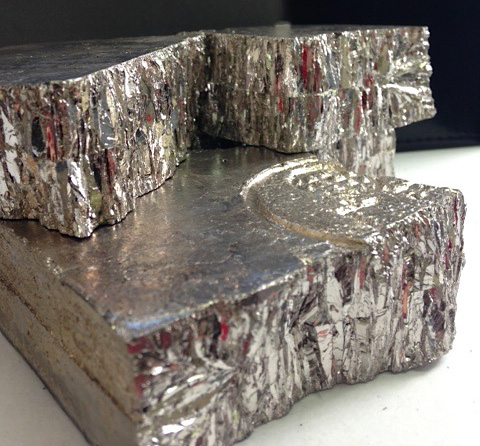

General Description

Appearance : Bright brownish-silver

Melting Temperature: 271.5 °C

Density: 9.78 g/cm3

Chemical Composition

Product Content (%)

Bismuth: 99.99

Element Max.Impurity (ppm)

Ag: 11

As: 1

Cu: 2

Fe: 3

Pb: 4

Te: 5

Sn: 2

Reviews